To Check and Ensure the Quality Characteristics, Performance and Consistency of Raw Rubber Compound and Product.

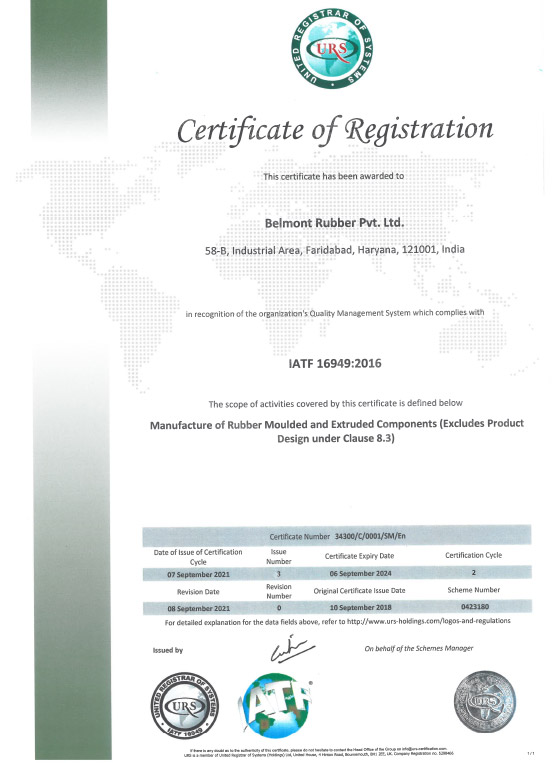

Total Quality Management and Customers Satisfaction are the Principle Values of Our Company and which is achieved by IATF 16949 Certified Quality Systems and passing the Parts through various In House Checks and Test Points during Production and Final stage and our Quality Assurance ensures to Deliver Defect Free Parts to our Esteemed Customers.

| Dimensions | I.D, O.D,Thickness,Length,Radius,Profile |

| Rheometer | The Cure & Processing Characteristics of Rubber Compound, as well as Physical Properties of the Material. |

| Hardness | Resistance to Permanent Indentation. Toughness and Softness |

| Tensile Strength | Rupture of a Specimen of Rubber Material. |

| Elongation Break | Stretching Strength of Rubber |

| Heat Ageing | Degradation of Physical Properties as Result of Exposure to High & Low Temperature Conditions. To predict the Performance of Material over Longer Times. |

| Oil/Liquid Ageing & Volume Swell | Softening & Increase in the Physical Size caused by the Swelling Action of a Liquid due to Absorption |

| Compression Set | Permanent Deformation of Rubber when a Certain Force at Certain Time and Temperature is applied and is Removed. |

| Tension Set | Recover Property after Stretched and Retract with Proportion of Applied Strain for a Certain Time and Temperature. |

| Adhesion | Bond Strength between Rubber to Fabric/Yarn or Rubber to Metal/Plastic |

| Specific Gravity | Weight of Product by Volume |

| Leakage | Failure due to Seeping of Liquid/Gas from Tube and Joint Areas |

| Bursting Pressure | How much Pressure of Liquid/Gas at Certain Temperature a Tube/Hose can Take/Withstand before Bursting |

| Ozone and Weather | Cracking & Ability to Withstand Weathering factors, such as: Oxygen, Ozone, Atmospheric Pollutants, Erosion, Temperature Cycling and Ultraviolet Radiation. |

| Special Test as per Customers Requirement | Besides above In House Tests Facilities, any other Test if Required can be arranged to Test from outside Certified Laboratory |